AISI T1 High Speed Steel India, AISI T1 High Speed Steel Ludhiana, Punjab

T1 High Speed Steel

T1 High Speed Steel stands out because of its balance state in terms of offering abrasion resistance property. And other features of AISI T1 High Speed Steel India, like good red hardness, high hardness, and high toughness, make it even better. Moreover, there are several applications whose use makes a huge difference to the entire state. The chemical composition and its balanced state make it an excellent quality material and outstanding on all levels.

Bk Steel Company customer-oriented service has helped gain thousands of customers’ trust as the leading steel distributor. Additionally, we are proud dealers of Gloria, Sanyo Special Steel, and Musco.

Equivalent Grades

| AMERICAN (AISI) |

DIN (W.Nr.) |

CODE |

JAPANESE (JIS) |

BOHLER |

| T-1 |

1.3355 |

HS18-4-1 |

SKH2 |

S 200 |

CHEMICAL COMPOSITION

| C |

Cr |

Mo |

W |

Co |

V |

| 0.75 |

4.1 |

– |

18.0 |

– |

1.1 |

STANDARDS

| USA |

Europe |

Germany |

France |

Sweden |

Japan |

| AISI T1 |

HS 18-0-1 |

1.3355 |

AFNOR Z80WCV.18.4.1 |

SS 2750 |

JIS SKH2 |

DELIVERY HARDNESS

| Typical soft annealed hardness is 260 HB |

Cold drawn and cold rolled material is typically 10-40 HB harder |

Features of T1 High Speed Steel

For a better understanding of why AISI T1 High Speed Steel Ludhiana, Punjab, stands out, here are some of its excellent features:

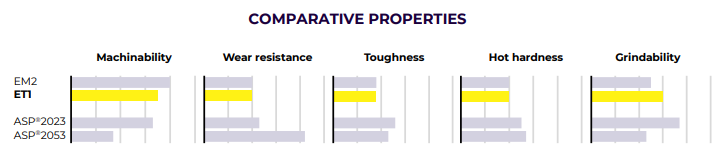

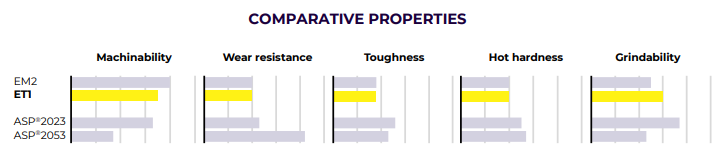

- High toughness

- High wear resistance

- Stabilized heat treatment

- Offers fine carbide distribution

- Stable performance because of uniformity

- High purity with the least inclusions and gases

- Good mechanical properties due to fine and uniform grain size

Form supplied for T-1 High Speed Steel

- Flat bars

- Square bars

- Sheets

- Discs

- Strips

Available surface conditions: drawn, ground, hot rolled, cold rolled.

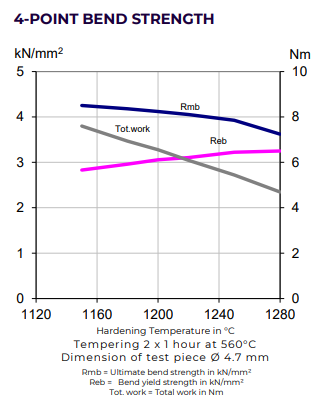

Heat Treatment for T-1 High-Speed Steel

- Soft annealing requires a protective atmosphere of around 3 hours with an 850-900°C. Then comes slow cooling to air cooling to 10°C per hour down to 700°C.

- Stress management for around 2 hours from 600°C to 700°C. Afterward, slow cooling to 500°C for desired results. For the steps mentioned above, preheating the atmosphere for hardening gives better results.

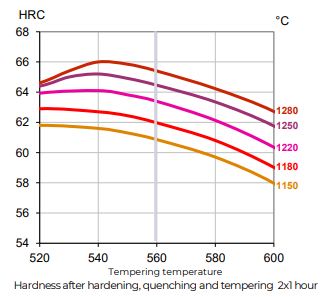

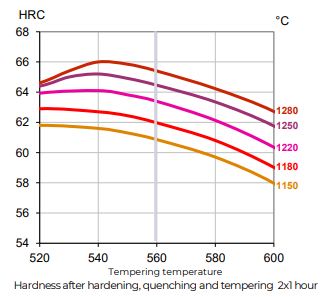

- Preheating results in 450-500°C and 850-900°C with the right temperature. Maintaining the right temperature is essential to get the right types of hardness.

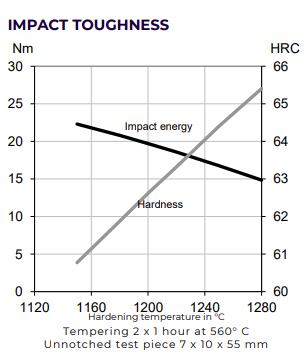

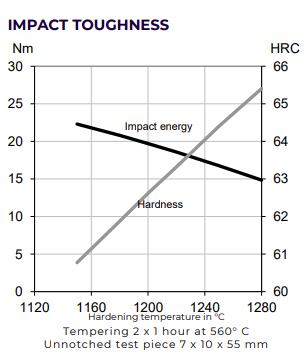

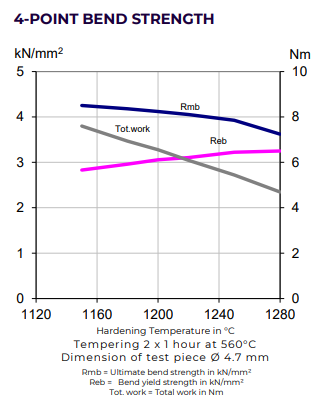

- Another imperative way is to handle everything for 1 hour at 560°C every time with two tempers.

Usage of T1 High Speed Steel

The T1 High speed steel is used for several options like:

- Gear tools

- Trailers

- Cranes

- Milling tools

- Complex blades

- Cold extrusion dies

- Bridge frames

- Earthmoving equipment

- Mining equipment

- High-temperature bearings

- Structural components

- Truck frames and bodies

- Impact-resistant metal cutting tools

- Other tools like cutters and punches

- Booms (lattice-type and telescopic)

- Transport vehicle frames and bodies

- Storage container support frames

- High-speed cutting tools (such as electric saws)

Surface Treatment

Surface treatment for steel grade makes an appropriate choice for PVD coating. In case there’s a small diffusion zone then better manage oxidized layers and compounds.

| Temperature |

20°C |

| Density g /cm3 |

8.7 |

Do you have any doubts?

Get hold of the Bk Steel professional team, clear your donuts, get a quote, and place the order.