- Search:

BK Steel Company is one of the reputable brand names for supplying D3 Cold Work Steel India at an affordable cost. We ensure never compromise in terms of quality and offer service that stands out on all possible levels. Our team makes sure to do enough market research to deliver the best possible end results.

Our customer-oriented approach and business functionality have made us a trusted name in the market. We stick to the necessary business values and ethics for delivering what’s best and the customers’ needs. In the AISI D3, 1.2080, X210Cr12, SKD1, and K 100, we follow all the specifications to ensure the best results are achieved, and customers get the necessary product searching for.

Cutting tools for sheets up to 4 mm thickness, trimming dies, blanking dies for paper and plastics, shear blades and rotary shear blades for sheet thicknesses up to 2 mm, drawing and deep-drawing tools. Woodworking tools, stone pressing tools, pressure pads and highly wear-resistant plastic moulds, profile rolls. The variety of applications and flexible approach plays an important factor for making the D3 Cold Work Steel Punjab have an increasing demand all around the globe .

| AMERICAN (AISI) | DIN (W.Nr.) | CODE | JAPANESE (JIS) | BOHLER |

| D-3 | 1.2080 | X210Cr12 | SKD-1 | K 100 |

| DIN | W.Nr | AFNOR | AISI/ASIM | JIS |

|---|---|---|---|---|

| X210Cr12 | 1.2080 | Z200C12 | D-3 | SKD1 |

| C | Si | Mn | P (max) | S (max) | Cr |

|---|---|---|---|---|---|

| 1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 0.03 | 0.03 | 11.0-13.0 |

| 20°C | 100°C | 250°C | 350°C | 500°C | 600°C | 700°C | |

|---|---|---|---|---|---|---|---|

| Coefficient of thermal expansion at °C 10-6 m/(W/mk) | 10.8 | 11.7 | 12.2 | 12.6 | 12.8 | 13.1 | 13.3 |

| Thermal conductivity at °C (W/mk) | 16.7 | – | – | 20.5 | – | – | 24.2 |

12 % ledeburitic chromium tool steel with extreme wear resistance.

Threading rolls and dies, cold extrusion tools, trimming, cutting and stamping tools for sheet thicknesses up to 6 mm, precision cutting tools for sheet thicknesses up to 12 mm, cold pilger mandrels, circular-shear blades, deep-drawing tools, pressure pads and highly wear-resistant plastic moulds.

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | HARDNESS | |

|---|---|---|---|---|---|

| Annealing | Heat to 800 – 840 °C | Min. H.T. for 2 minute /mm | Furnace | max. 250 | |

| Stress relieving | Heat to 650 – 700 °C | Min. H.T. for 2 minute /mm | furnace | – | |

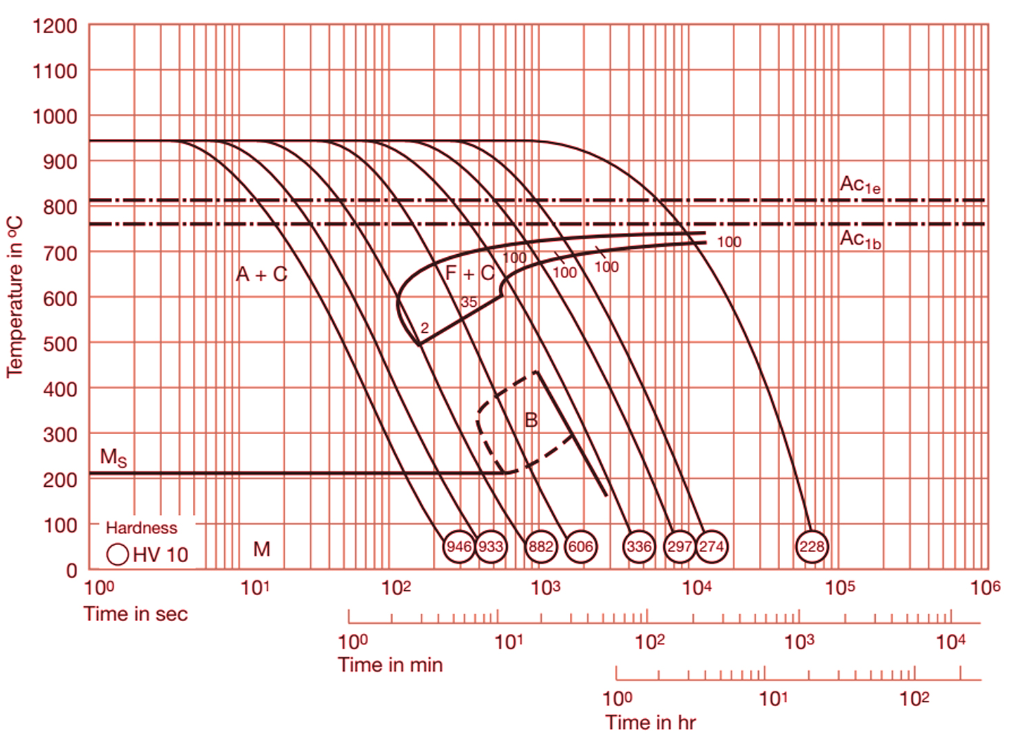

| Hardening | Heat to 930 – 960 and 950 – 980 °C | Min. H.T. for 1 minute /mm | oil Air (up to 30 mm thickness) | 64 | |

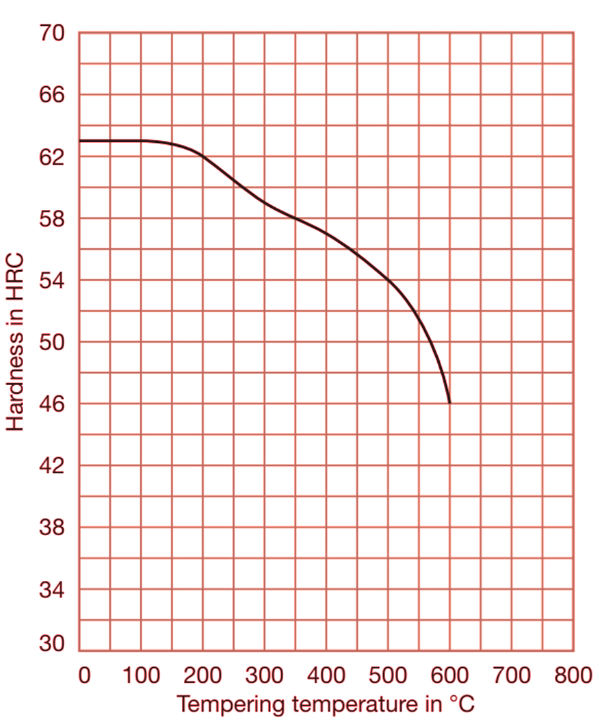

Hardening temperature HRC

| °C | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 63 | 62 | 59 | 57 | 54 | 46 |

BK Steel Company offers only the products that call for quality and serve the most exceptional results. Our service has made us the first choice for several clients who have been in search of the D3 Cold Work Steel in Punjab, India. Moreover, all the necessary products are available at an affordable cost.

If there’s any doubt or concern, then feel free to ask the team about the same. You should email mentioning all the necessary information you have been looking for, or you can give us a call. Our experienced team will ensure all your doubts are cleared and even give you the quote to consider the fair amount on which all the necessary products are available with us.