- Search:

Have you searched for the finest quality plastic mould steel of AISI standards? Bk Steel Company offers you the same. We have the most quality and standardized AISI: P20 + Ni HH Plastic Mould Steel India. As a team, we make sure to serve what’s best and stand out on all different levels. Ensure that the final product delivered to you fulfills all your project requirements.

We are not just known for our customer-oriented service but for ensuring all the necessary industry protocols are followed. The reason for the success is putting in endless efforts all the time. Moreover, we are also the proud dealers of:

If there’s any other important specification or doubt on your mind, then feel free to talk to the team.

VR400 offers high hard tool steel offering a thickness of around 1300 mm. The thickness helps to make blocks of different sizes with exceptional performance and hardening homogeneity. Additionally, it stands out perfectly in plastic injection moulds, big size moulds, and compression moulds. The properties allow it to be used in texturing and the automotive industry. The improved performance and overall design offer several benefits:

| AMERICAN (AISI) | DIN (W.Nr.) | CODE | BOHLER |

| P-20 + Ni HH | 1.2738 HH | 40CrMnNiMo8-6-4 / VR 400 | M238 |

| DIN | W.Nr | JIS |

|---|---|---|

| VR400 | 1.2738 HH | – |

| C | Si | Mn | P (max) | S (max) | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.27-0.30 | 0.03 | 1.50-1.60 | 0.010 | 0.001 | 1.20-1.40 | 0.45-0.60 | 1.05-1.20 |

EAF – LF – VD – Forging – Heat treatment QT

In according to standard EN10228-3 Class 4 and standard SEP 1921 Class E/e

VR400 is delivered in quenched and tempered condition, with hardness range 360 – 400 HB (39 – 43 HRC).

The high performance of hardenability for thickness 1300 mm, is obtained by an optimized balance of chemical composition and a special manufacturing process.

![]()

| 20°C | 100°C | 250°C | 500°C | |

|---|---|---|---|---|

| Thermal expansion coefficient (10-6/K) | 11.4 | 11.6 | 12.7 | 14.2 |

| Thermal conductivity (W/mk) | 36 | 36.7 | 38 | 34.3 |

| Young modulus (Kn/mm2) | 211 | 207 | 199 | 166 |

| TREATMENT | TEMPERATURE | HOLDING TIME (HT) | COOLING | COMMENTS | |

|---|---|---|---|---|---|

| Annealing | Heat to 650 – 700 °C | Min. H.T. for 2 minute /mm | Air or furnace | In order to obtain hardness lower than 250 HB ( 24 HRC) to improve machinability | |

| Stress relieving | Heat to 500 – 550 °C | Min. H.T. for 2 minute /mm | Air or furnace | To be carried out after machining, is recommended to eliminate the residual stresses induced by mechanical working | |

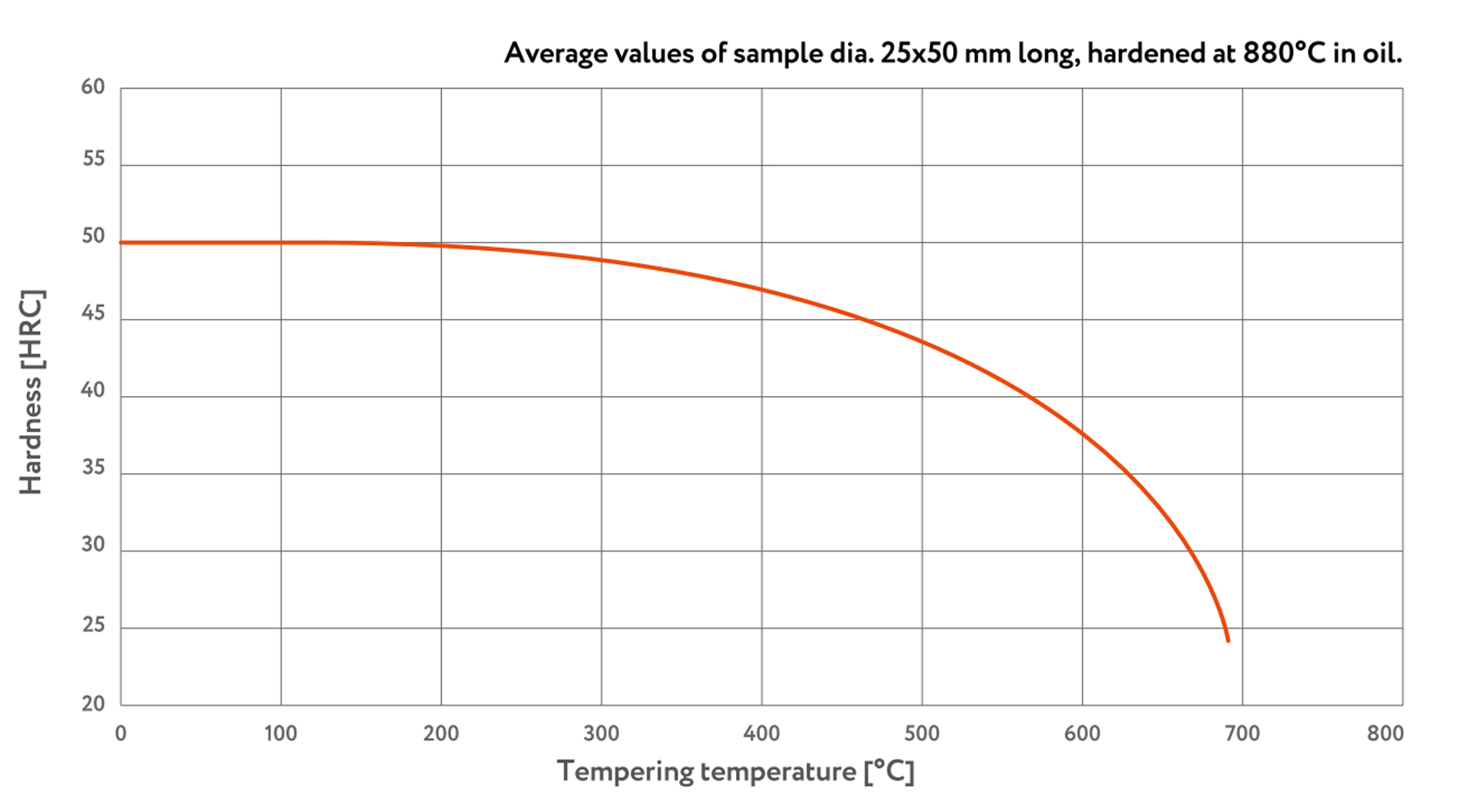

| Hardening | Heat to 860-900°C | Min. H.T. for 1 minute /mm | Polymer | – | |

| Tempering | Heat to 550 – 610°C | Min. H.T. for 3 minute /mm | Air or furnace | To be carried out after hardening. 2nd Tempering must be performed to max 30°C below tempering temperature | |

Bk Steel Company works tirelessly every year to guarantee what’s best and come up with the options that stand apart on all levels. We aim to ensure that whosoever client needs a specific product gets the same, and all of their project demands are fulfilled on time.

Feel free to talk about the same to the team. After considering everything and going through doubts, the team will guide you towards the best possible approach. You can even drop us an email mentioning all the necessary information you want. And one of our team members will get back to you soon.

![]()

![]()

![]()

![]()

Texturing performed by Standex Mold-tech with patterns Standex MT 9086, MT 9055 and 9083

![]()